Categoria de producto

HDP Homogeneous & Emulsification Pump

Artículo No.:

HLS-D001

Resumen

Palabras Clave: Bomba Lobular Rotativa、

TEL:

TEL/Whatsapp/Wechat:

E-mail:

Detalle del producto

- Description

- Performance

- Parameters

-

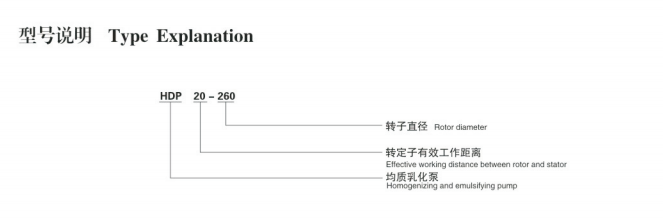

- Nombre del producto: HDP Homogeneous & Emulsification Pump

- Código de producto: HLS-D001

HDP homogeneous emulsion pump is composed of 3-5 layers of rotor and stator. The tooth clearance of each layer of rotor and stator is from coarse to fine. The material enters into the pump cavity for layer by layer crushing, dispersion, fine, homogenization and emulsification.

Product introduction:

HDP homogeneous emulsion pump is composed of 3-5 layers of rotor and stator. The tooth clearance of each layer of rotor and stator is from coarse to fine. The material enters into the pump cavity for layer by layer crushing, dispersion, fine, homogenization and emulsification. HDP is a kind of high-performance ultra-fine homogenization pump which integrates crushing, dispersion, disaggregation, mixing, fine, homogenization, emulsification and transportation. Compared with hep series homogenization pump, HDP homogenization pump has better grinding effect on granular materials.

-

High pressure rotor pump manufacturers rotor pump gas damage and cost will be very large. The idling of rotor pump leads to the damage of several components, one pump shell, inner magnetic steel, outer magnetic steel, static ring, centrifugal impeller, protective sleeve, pump shaft, thrust ring, sealing ring, etc. In the whole process of rotor pump application, waiting for speed is a lot of unsuccessful reasons. Therefore, customers should master that the rotor pump is not spare. I will briefly explain why the rotor pump is not allowed to be idle. The key reasons are as follows: 1. The rotor pump can not be idle. Because the rotor pump of magnetic cylinder is composed of refrigeration materials, if the gas will cause the magnetic cylinder lock. 2. The rolling bearings of rotor pump motor rotor are mostly made of cemented carbide tools, which are lubricated by materials, but the pump can not be lubricated. 3. After the pump is empty, there is no raw material cooling pump, so it is possible to ignite the diaphragm immediately. 4. The key components of corrosion-resistant rotor pump are external magnetic component and internal magnetic component. If idling, key components will be demagnetized at high temperature and rotor pump characteristics will be greatly reduced after demagnetization.

-

PRODUCTOS PRINCIPALES

EXPLORA NUESTRA LÍNEA DE PRODUCTOS

Rotary Lobe Pump

The rotary Lobe Pump is a kind of positive displacement pump. There is a pair of synchronous counter rotating cams in the pump cavity. Hollysys fluid technology has always been committed to combining the product with practical application, continuously upgrading and improving the product.

Aprende más +

Rotary Lobe Pump

The rotary Lobe Pump is a kind of positive displacement pump. There is a pair of synchronous counter rotating cams in the pump cavity. Hollysys fluid technology has always been committed to combining the product with practical application, continuously upgrading and improving the product.

Aprende más +

Rotary Lobe Pump

The rotary Lobe Pump is a kind of positive displacement pump. There is a pair of synchronous counter rotating cams in the pump cavity. Hollysys fluid technology has always been committed to combining the product with practical application, continuously upgrading and improving the product.

Aprende más +

Rotary Lobe Pump

The rotary Lobe Pump is a kind of positive displacement pump. There is a pair of synchronous counter rotating cams in the pump cavity. Hollysys fluid technology has always been committed to combining the product with practical application, continuously upgrading and improving the product.

Aprende más +